- Aberdeen Oil Works

- Addiewell Oil Works

- Almondhill Oil Works

- Annick Lodge Oil Works

- Arden Oil Works

- Armadale Oil Works

- Auchenheath Oil Works

- Avonhead Oil Works

- Balgray Oil Works

- Ballat Oil Works

- Bathgate Oil Works

- Bathville Oil Works

- Bellsdyke Oil Works

- Bellsquarry Oil Works

- Benhar Oil Works

- Binnend Oil Works

- Birkenshaw Oil Works

- Bishop Street Oil Works

- Blackburn Oil Works

- Blackstone Oil Works

- Blackstoun Oil Works

- Blochairn Oil Works

- Boghall Oil Works

- Bredisholm Oil Works

- Breich Oil Works

- British Asphalte Oil Works

- Broxburn Oil Works

- Broxburn - Bell's Stewartfield Oil Works

- Broxburn - Albyn Oil Works

- Broxburn - East Mains Oil Works

- Broxburn - Greendykes Oil Works

- Broxburn - Hallfarm Oil Works

- Broxburn - Hutchinson's Oil Works

- Broxburn - Poynter's Oil Works

- Broxburn - Steele's Oil Works

- Broxburn - Steele's Stewartfield Oil Works

- Buckside Oil Works

- Burngrange Oil Works

- Calderbank Oil Works

- Canalbank Oil Works

- Champfleurie Oil Works

- Clippens Oil Works

- Cobbinshaw North Oil Works

- Cobbinshaw South Oil Works

- Coneypark Oil Works

- Craigie Oil Works

- Crown Point Oil Works

- Dalmeny Oil Works

- Deans Oil Works

- Doura Oil Works

- Drumbow Oil Works

- Drumcross Oil Works

- Drumgray Oil Works

- Dryflat Oil Works

- East Fulton Oil Works

- East Hermand Oil Works

- Eldin Oil Works

- Falkirk Oil Works

- Fergushill Oil Works

- Forthbank Oil Works

- Forth & Clyde Oil Works

- Gavieside Oil Works

- Grange Oil Works

- Grangepans Oil Works

- Greengairs Oil Works

- Hareshaw Oil Works

- Hartwood Oil Works

- Hawick Oil Works

- Hermand Oil Works (1866)

- Hermand Oil Works (1883)

- Holmes Oil Works

- Hopetoun Oil Works

- Hurlford Oil Works

- Inkerman Oil Works

- Inverkeithing Oil Works

- Kilrenny Oil Works

- Kilwinning Oil Works

- Kirkmuirhill Oil Works

- Kirkwood Oil Works

- Lanark Oil Works

- Lanemark Oil Works

- Levenseat Oil Works

- Limerigg Oil Works

- Linwood Oil Works

- Loanhead Oil Works

- Lochburn Road Oil Works

- Lochgelly Oil Works

- Longrigg Oil Works

- Magdalene Oil Works

- Methil Oil Works

- Millburn Oil Works

- Nettlehole Oil Works

- Niddry Castle Oil Works

- Nitshill Oil Works

- Oakbank Oil Works

- Palacecraig Oil Works

- Pathhead Oil Works

- Patterton Oil Works

- Pentland Oil Works

- Philpstoun Oil Works

- Port Dundas Oil Works

- Possil Oil Works

- Pumpherston Oil Works

- Raebog Oil Works

- Riggend Oil Works

- Rochsoles Oil Works

- Rochsolloch Oil Works

- Roman Camp - Almondfield Oil Works

- Roman Camp - Cawburn Oil Works

- Roman Camp Oil Works (1892)

- Roman Camp - Shale Oil Works

- Rosebank Oil Works

- Roughcraig Oil Works

- Rumford Street Oil Works

- Seafield Oil Works

- Shawsburn Oil Works

- Sheepford Locks Oil Works

- Shettleston Oil Works

- Shotts Oil Works

- Stand Oil Works

- Stanrigg Oil Works

- Stonehouse Oil Works

- Straiton Oil Works

- St. Rollox Works

- Swinehill Oil Works

- Tarbrax Oil Works

- Uphall Oil Works

- Uphall - Railway Oil Works

- Uphall - Wyllie's Oil Works

- Vulcan Chemical Works

- Wardend Oil Works

- Wattston Oil Works

- Westfield & Capeldrae Oil Works

- Westwood Oil Works (1941)

- Westwood Oil Works (1866)

- Whitebog Oil Works

- Whitehill Oil Works (Lanarkshire)

- Whitehill Oil Works (Midlothian)

- Whiterigg Oil Works

- Woodhall Oil Works

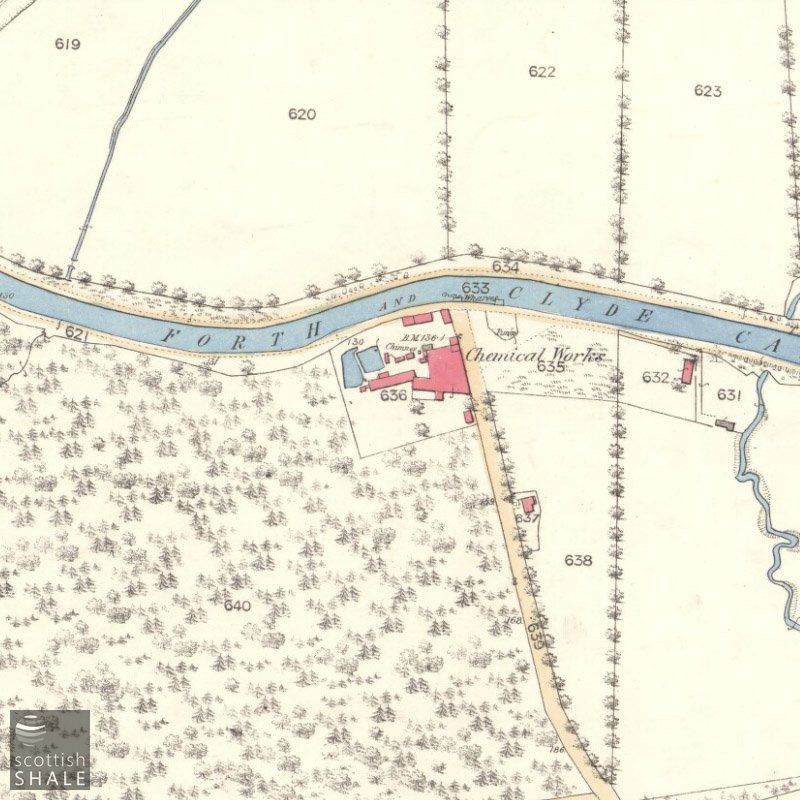

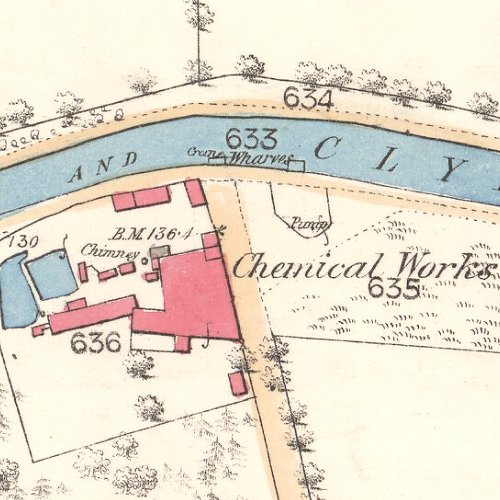

Falkirk Oil Works

Redwood lists a "Ross Oil Works" located at "Fauldkirk" and active between 1864 and 1865.

In 1845, James Ross & Company, tar distillers, established a works at Lime Wharf, beside the Forth and Clyde canal in Falkirk. It appears that for a period, the company also retorted shale and refined crude oil on that site. James Ross & Company were associated with shale oil operations at Riggend Chemical & Oil Works, and in 1882 established the Philpstoun Oil Works.

The Falkirk Tar works developed into a substantial industrial site, laterly operated by Scottish Tar Distillers. The works were seriously damaged by fire in 1973, and closed during the 1980's.

Mapped by the Ordnance Survey of c.1864.

Recent images

Site of the earliest part of the works, beside the Forth and Clyde canal. Looking east. January 2012.

View towards the canal. Looking north. January 2012.

Premises of Siboro Ld, manufacturers of lubricants and industrial additives, who continue to operate from the former tar works site. Looking north east. January 2012.

Evidence of James Ross, Paraffin Oil Manufacturer, Falkirk, Stirlingshire. My works are situated on a small stream, a tributary of the River Carron, an affluent of the Forth. Employ 90 hands. Rateable value of works, £162 8s. The bed of the stream is not silted up. My works are not affected by floods. The condition of the stream has not changed during the last 30 years within my knowledge. I am not aware that it is polluted by works above, but it is to a certain extent by mines. Obtain supply of water jointly from the stream and from the Forth and Clyde Canal, and consume 10,000,000 gallons yearly. I use yearly the following materials:- Bituminous shale 6708 tons; sulphuric or other acid, 430 tons; caustic soda or other alkali, 80 tons. Produce yearly, naphtha, 120,000 gallons; crude paraffin, 450,000 gallons; lubricating oil, 58,000 gallons; illuminating oil, 180,000 gallons; coal tar pitch, 1700 tons; sulphate of ammonia, 230 tons; scale paraffin, 100 tons; creosote oil, 170,000 gallons; gas tar and ammoniacal liquor, 1,380,000 gallons. Produce yearly liquid refuse from the following processes: - Condensed water separated from tar after removal of naphtha, 550,000 gallons; spent sulphuric acid after first purifying process, 150,000 gallons; spent caustic soda and tarry matter after second purifying process, 60,000 gallons. The condensed water is run direct into the stream; the acid and alkali with the waste products are utilised. We produce yearly 5000 tons of spent shale, which is stored in heaps to be made into bricks as soon as practicable. Use steam, 54 nominal horse-power. Consume yearly 5500 tons of coal, and make about 550 tons of ashes, part of which are ground and mixed with lime for building purposes. The excrements of my work people are removed from dry earth closets, and are used for manure. We have no suggestions to offer as to the best means of avoiding pollution in future, but should not object to rivers and streams being placed under Government inspection, by practical men, but are decidedly averse to unnecessary restrictions on manufactures, considering that there is far too much of such already.

Report on the pollution of Scotch rivers to the Rivers Pollution Commissioners, as reported in The Falkirk Herald, 28th August 1873